Find the perfect fit.

We pride ourselves on our world-class OEM service that fosters collaboration with our clients, helping them find their perfect combination of condom design and packaging.

Private Label Condom Design Options

Surface Texture

- Smooth

- Textured

Colour

-

Natural

Translucent and without added colouring. -

Coloured

Added with pigments suitable for use in medical devices.

Scent & Flavouring

-

Plain

Natural “sweet” scent of pre-vulcanised latex. -

Flavoured

Added with food-grade flavouring agents.

Dimension

- Length = 170 mm (min.)

- Width = 49 mm and 53 mm (±2 mm)

- Thickness = 0.065 ±0.015 mm (mean single-wall), 0.055 ±0.005 mm (ultra thin condom)

Performance Testing

Testing: In accordance with test method in ISO 4074:2002.

Sampling: In accordance with ISO 2859-1.

AQL : Acceptable quality level.

Air Volume

| Before aging |

Min. Required : 18 L

Mean Tested : 35 L |

| *After aging | Min. Required : 18 L

Mean Tested : 35 L |

Air Pressure

| Before aging | Min. Required : 1 kPa Mean Tested : 2.0kPa |

| *After aging | Min. Required : 1 kPa Mean Tested : 1.9kPa |

Every condom is screened for holes by Electronic Testing machine. Further random testing is conducted using Electrolyte Testing machine.

Detection of condoms with visible defects such as broken, missing or distorted rim, dirt, etc.

Detection of leakage of lubricant from condom package.

- Condoms are made of natural rubber latex.

- Condoms coated with suitable dusting powder (e.g. corn-starch and magnesium carbonates) to prevent sticking.

- Condoms are lubricated with silicone oil (i.e. 550 ± 150mg).

Not more than 5 years from date of manufacture.

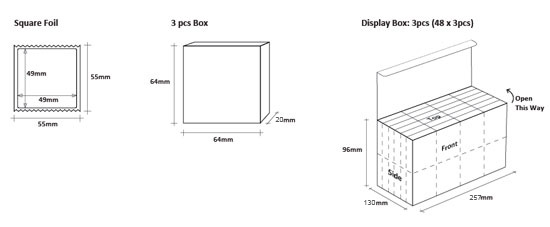

Packaging Design

Foil and box packaging tailored to your needs